Q&A: Integrated Solar

Marty Low is CEO of SRS Energy, a Philadelphia-based developer of integrated solar roofing products that provide renewable energy while  serving the structure functionally and aesthetically.

serving the structure functionally and aesthetically.

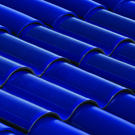

The company’s Sole Power tile is designed to blend with several styles of the US Tile Co.’s clay roofing tiles, eliminating the need for obtrusive solar arrays. The product has earned a number of accolades from various industry publications, and it was the recipient of the 2010 Edison Best New Product award for industrial design. Low spoke with Green Building News during a phone interview.

Q: Do you thing integrated photovoltaics are a future trend in the solar industry?

A: Yes, integrated photovoltaics usually are implemented in new construction, and if you talk to the roofing companies they think that building integrated will be the wave of the future.

Solar companies that just sell technology or solar panels will eventually create products that become part of the roof — products that will be much more integrated into the building envelope then they are currently. I would imagine in 10 to 15 years, the majority of solar installed will be in some kind of integrated form.

Q: What are some of the benefits and disadvantages of the integrated solar systems versus bracketed systems?

A: Right now, if you have a commercial flat roof and there’s no issue of aesthetics because people can’t see it, costs per watt to install a bracketed system is going to be lower. There’s a disadvantage to using a fully integrated solution if the purchaser is only concerned about how much power they can get out of the system for how much money.

If the building owner is concerned at all about aesthetics, they might tend toward a building integrated solution. Some integrated solutions basically feign or imitate the rooftop but truly aren’t designed and built in such a way that they are supposed to last for 20 or 30 years. Something unique about our product is that it is a roofing product first and solar product second.

Q: How do bracketed and integrated systems compare in the amount of energy they are able to produce?

A: That can be seen as a disadvantage to integrated photovoltaics. There are different kinds of solar technology out there. Crystalline silicon, which is typically what they put in the bracketed modules, is a brittle material that can only be encased in glass, which means it has to be flat. Amorphous silicon is flexible and can be encased in a flexible laminate and bent.

The amorphous silicon is less efficient than the crystalline silicon is in terms of a rated watt output. What that means is if I want to put up a certain sized system, I will need more of the amorphous silicon then I will need of the crystallized silicon to create the same output. So our disadvantage, to some extent, is that it requires more roof space because the efficiency of the building to generate power per square foot with amorphous is less than if it used crystalline.

But, while the rated capacity of crystalline is better, the actual production per rated capacity is actual better with amorphous. If I install a 5-kilowatt system with crystalline and 5-kilowatt system with amorphous, in terms of how much electricity I will produce at the end of the day, the amorphous is better because it captures diffused light better. In places where it’s cloudy, amorphous will perform better. Also, in places where it’s hotter, amorphous performs better than crystalline.

Q: How do you make your integrated products made as durable as standard roofing products?

A: We start with a roofing material that will last on the roof for 20 or 30 years and we have a technology that enables us to integrate the amorphous silicon into that roofing profile. At the end of the day, you have a roof that lasts and a product generates solar power. We don’t imply that the solar technology alone is adequate to protect the roof. We actually have a polymer substrate that enables it to perform that function.