Career & Technical Education Pushes New Construction Trend

By Daedalus Howell

BELLE FOURCHE, S.D. — Earlier this month, the local school district of Belle Fourche convened a meeting to move forward on awarding a nearly $3 million bid for the construction of a proposed Career and Technical Education (CTE) building. The proposed structure is not only a place to train high school students in industries as diverse as welding, family and consumer science, hospitality and agriculture, it’s also representative of a trend working its way across the nation.

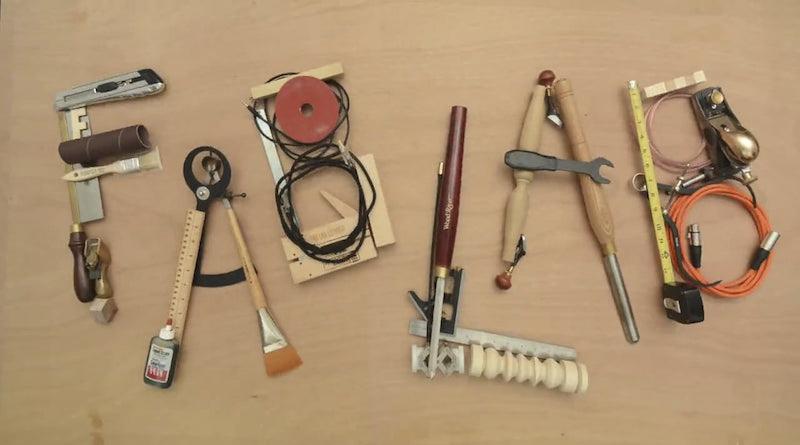

Presaged by what were once known as vocational or trade high schools, the Career and Technical Education movement is seeing high schools throughout the U.S. launching programs shaped specifically to provide students with contemporary career skills. This isn’t the “shop class” of yore, however, as many of these facilities contain digital fabrication laboratories, or “Fab Labs” for short, that feature an array of technology such as CAD design stations and 3-D printers.

Sarah Boisvert, founder of Fab Lab Hub, a non-profit associated with the MIT Fab Lab Network that helps start new makerspaces, conducts workforce and entrepreneurship training in digital fabrication, credits the job market for spurring part of the CTE trend.

“A large part of the change is driven by the need in manufacturing and high-tech [sectors] for workers skilled in ‘new collar jobs,’” she observed.

For those unfamiliar with the parlance, a new-collar job (as the New York Times recently framed it) is one that puts less emphasis on a college pedigree and more on specialized tech skills. This growing trend in the job market dovetails with school curricula that emphasize project-based learning and the push for increased science, technology, engineering and math education popularly known by its acronym STEM.

“Making things directly as part of projects integrates STEM subjects that are needed for New Collar Jobs,” said Boisvert, who points to Cleveland’s MC2 High School as an example of a school using a Fab Lab across its curriculum.

On the practical side, buildings that house the kind of technology required by a Fab Lab have special requirements. Ventilation is key when it comes to running 3-D printers, which emit fumes; likewise, CNC machines (“computer numeric control” tools used in prototyping in materials such as wood, plastics and aluminum) can produce flammable dust. Some labs will also require sound dampening and additional safety features like special enclosures and three-phase electrical wiring.

“Some of the machines can be large format, so additional space might be required, although smaller equipment can be used in Fab Labs with limited space,” said Boisvert. “In the philosophical sense, the Fab Lab needs to be accessible to the entire community, so it cannot be tucked away in the math or science department. Many schools are adding them to the library where students from across the school congregate.”

CTEs are proving vital to local economies due to the so-called “greying of America” as large swaths of skilled Boomer-aged workers reach retirement age.

“There is a shortage of skilled labor in the building trades,” said Tom Helminen, president of Hounghton, Mich.-based Moyle Construction to the Daily Mining Gazette. “[It] will only worsen going forward, as much of the current labor force reaches retirement age over the next decade. It is vital to our community that we provide CTE classes in our schools for students who wish to pursue a career path in the building trades.”

With more than 1,200 Fab Labs in her network alone, Boisvert believes the trend is here to stay, thanks in no small part to the Maker and DIY movements.

“A broader range of kids are showing interest in training for new-collar jobs; 3-D printing and lasers are pretty cool,” she said. “Plus, these kids are digital natives, so computers are an integral part of their lives. Smartphones are ubiquitous across socioeconomic lines, making interest in digital learning natural.”

Another factor driving highs school CTE programs is the fact that many offer certified professional training.

“A modern CTE program can include many things, but an emerging trend that can help students standout amongst their peers is the ability to earn industry-backed certifications,” explained Danny Paulmeyer of C. Blohm & Associates Inc., which provides digital marketing to the education industry. “An industry-backed certification is created when a CTE curriculum provider and a respected industry employer create a course and a year-end exam together that provides students with a certification through the employer that proves the student’s mastery of the subject.”

According to Paulmeyer, during the 2016-17 school, students earned more than 5,000 certifications from industry partners such as Southwest Airlines, which was a 190 percent increase from the previous year.

With an increased national need of new-collar workers and growing implementation of project-based learning, those in businesses related to school construction could see a steady stream of CTE buildings coming up for bid in the coming years — that is until some student figures out how to build them with a 3-D printer.